Robot Ranchers Could Maintain Future Wind Farms

We all know that the need of the hour is alternative energy so that future generations can still breathe fresh air and have enough energy for their industrial purposes and domestic use. Many states and countries are promoting wind energy as a clean and green energy. We all know the advantages and disadvantages of alternative energy. No doubt harvesting wind for energy purposes is a good move but maintenance of wind farms has its share of headaches. Wind turbine generators already mark the horizon for miles in every direction in many parts of the world. But maintenance of the windmills has been a strenuous task for human technicians. Rotor blade damage is a routine but irritating problem that demands many hours of maintenance.

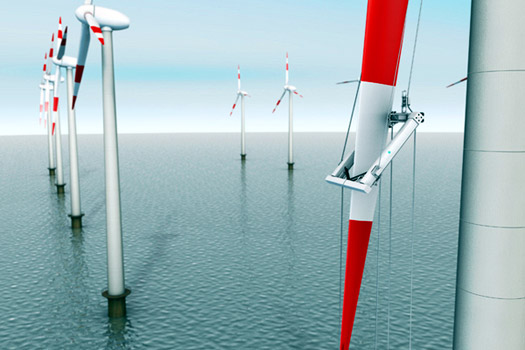

Now scientists at the Fraunhofer Institute for Factory Operation and Automation (IFF) in Germany have said they are developing a generation of robots which will be capable enough to monitor and maintain wind turbine generators on a round-the-clock basis. Their latest creation is RIWEA. It is a robot that inspects the rotor blades of wind energy converters.

It seems that wind energy converters bear the onslaught of weather all the time and in the process wear and tear of rotor blades is the normal phenomenon. So spotting out the damaged part in wind energy devices is quite challenging for humans. Often they have to perform this task at many feet above the ground where rotors are located. Rotor blades are made up of glass-fiber resistant plastics. Rotor blades have to endure wind, inertial forces, erosion, and other forces. Till now human beings have been shouldering the responsibility of inspecting wind energy converters at regular intervals. It turns out to be a time-consuming process that involves the technicians closely examining large surfaces. A rotor blade can be of 60 meters in length situated at windy heights. Now researchers are taking the help of Robot Ranchers to inspect windmills. They can perform the job more precisely than humans. Robot Ranchers can identify the minutest damage — even below the surface.

Dr. Norbert Elkmann, a project manager at the Fraunhofer IFF, says, “Our robot is not just a good climber. It is equipped with a number of advanced sensor systems. This enables it to inspect rotor blades closely.” The researchers are trying to consign, “inspection by humans” to history books.

The inspection system by Robot Ranchers consists of three components. Robot’s infrared radiator conducts heat to the surface of the rotor blades. This robot also has a high resolution thermal camera. This thermal camera records the temperature patterns and this helps in determining the flaws in the material. These robot ranchers are also equipped with an ultrasonic system and high resolution camera that would help in spotting damages which is difficult for humans to detect with naked eye. The greatest advantage of Robot Ranchers is its precision. It finds out the hairline cracks or other probable problems with great accuracy. A specially developed carrier system ensures that the inspection robot is guided securely and precisely along the surface of a rotor blade.